Innovating EPS Solutions for a Sustainable Future

Who Are We

Welcome to EPACK Petrochem Solutions, India’s leading Expandable Polystyrene (EPS) resin manufacturer and a trusted global EPS supplier. Leveraging decades of EPS processing expertise, our state-of-the-art manufacturing facility in Dahej, Gujarat produces premium-grade EPS raw materials innovative EPS solutions to clients worldwide. Our fully automated DCS-controlled plant ensures safe, consistent, and error-free large-scale production. Every batch undergoes rigorous multi-stage testing in our advanced process control laboratory to guarantee global-standard quality. Partner with us for quality, sustainability, and leadership in EPS manufacturing.

About EPACK Group

Redefining Industries Since 1999

EPACK Durable Limited

EPACK Prefab Technologies Limited

EPACK Petrochem Solutions Pvt. Ltd.

Why Choose EPACK Petrochem?

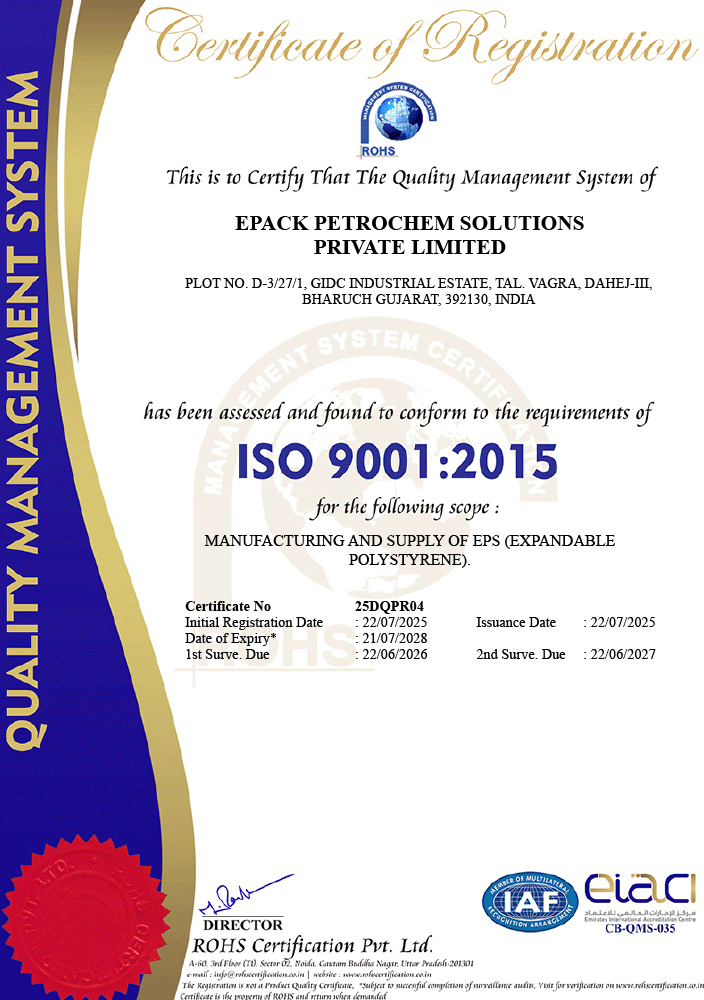

ISO Quality Management System Certification

🌍 Quick Update

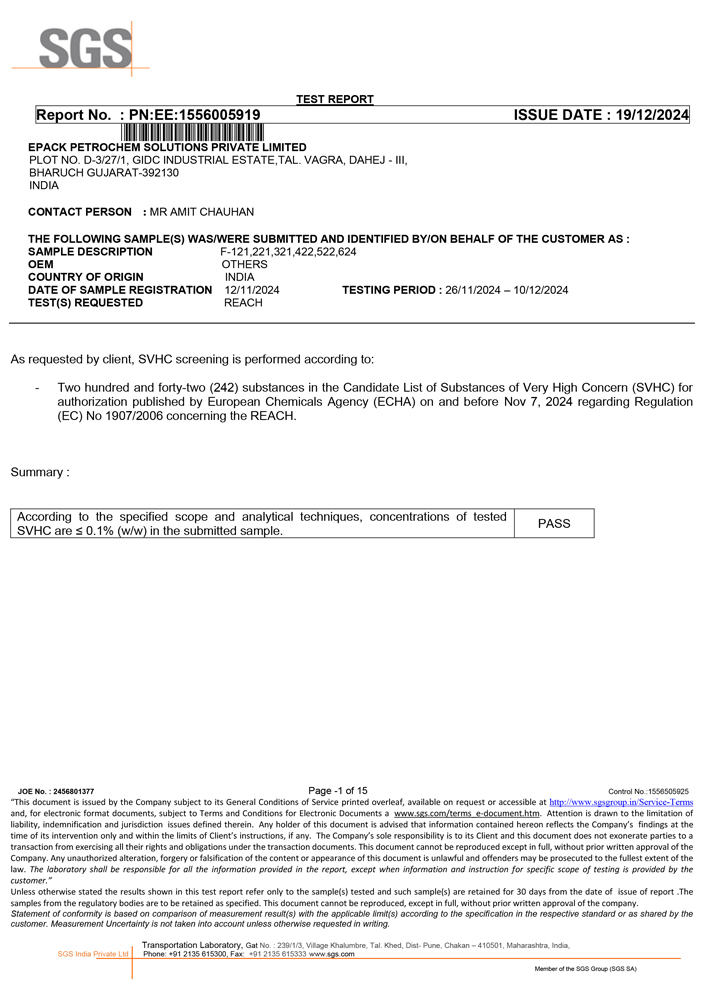

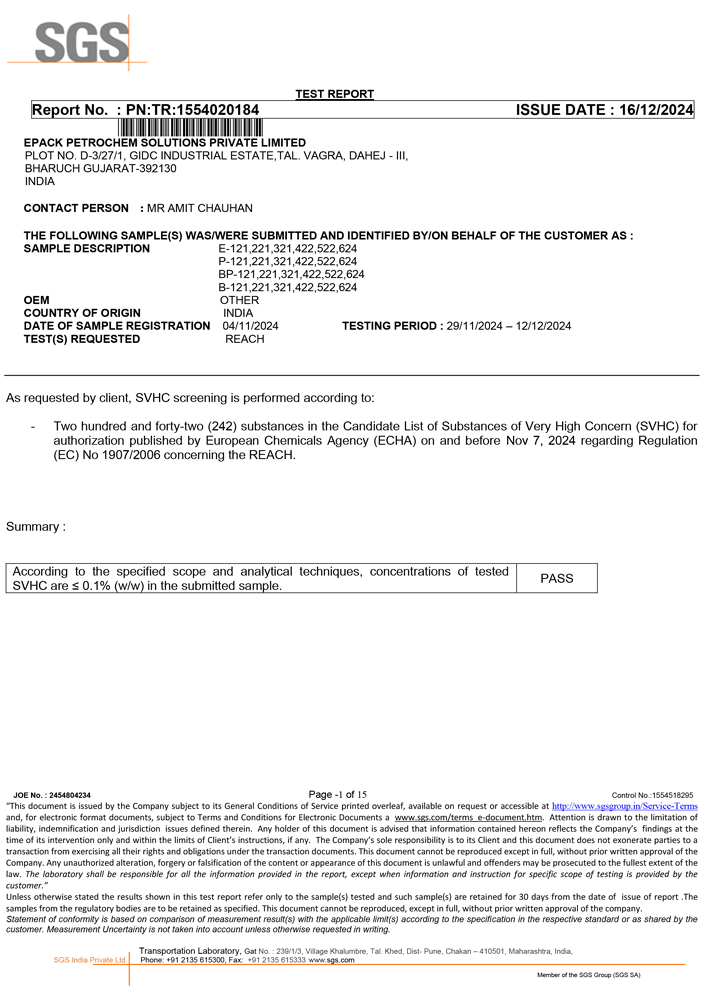

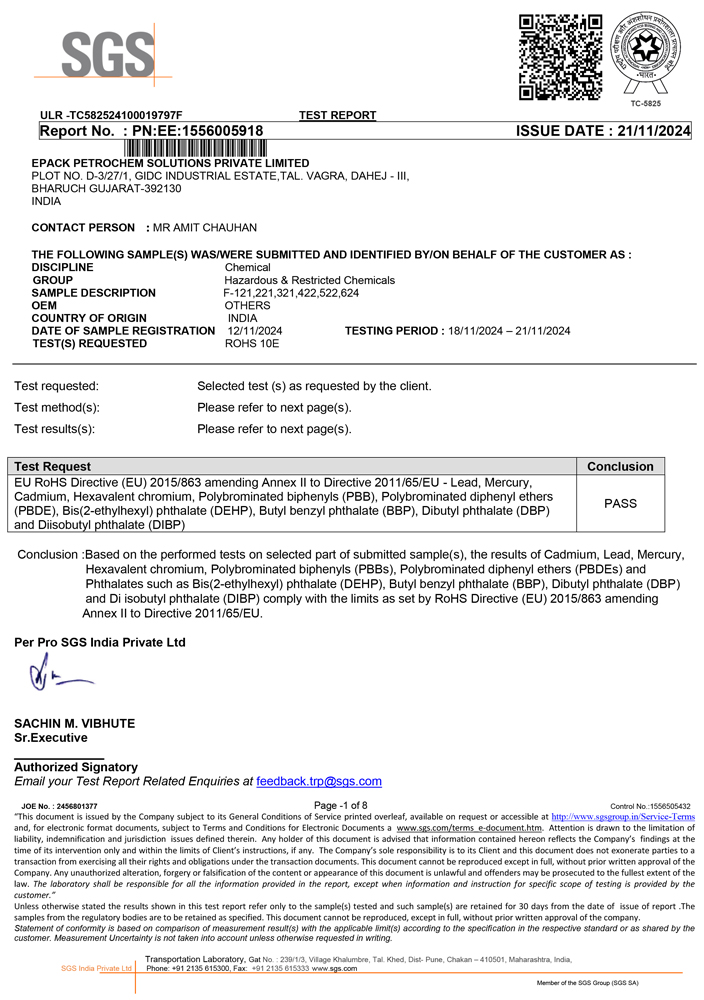

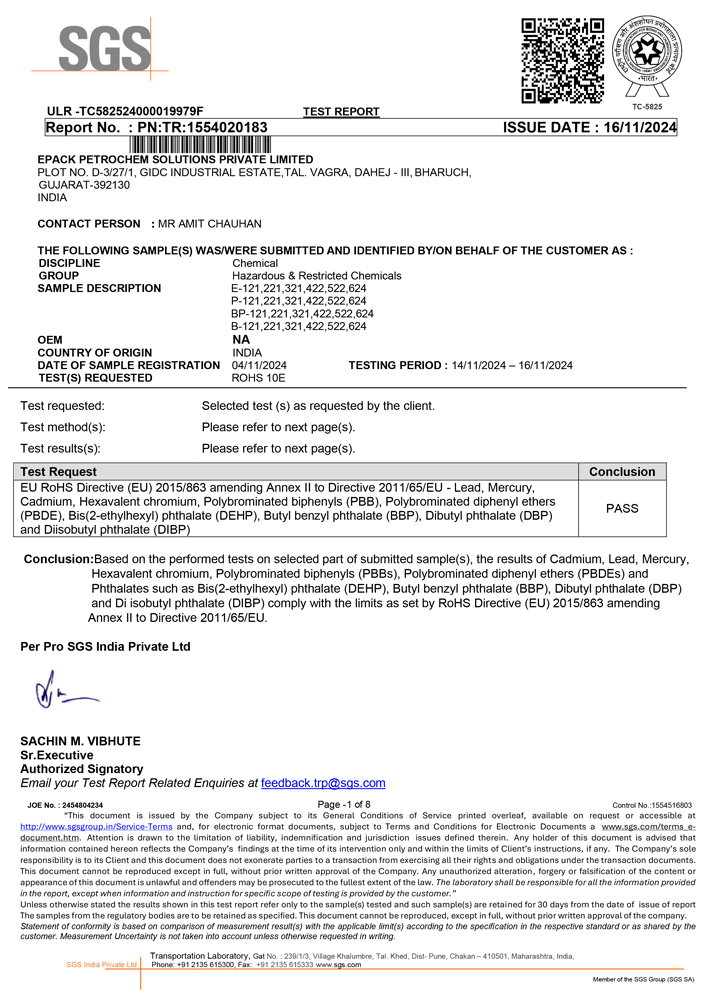

EPS Resin Supply Now Fully EU-Compliant

Why choose India over China for your EPS resin supply?

Supply Security

Cost Efficiency

Faster Delivery

Guaranteed Compliance

Global Reach

We supply and export to Sri Lanka, Saudi Arabia, UAE, Qatar, Egypt, Nepal, Europe, South America, and more—backed by robust logistics, on-time delivery, and compliance with international quality guidelines.